Product Features :

■ The hydraulic press is suitable for automobile longitudinal girder drawing, pressing ,and forming process, also can be engaged in other metal sheet pressing molding and calibration process.

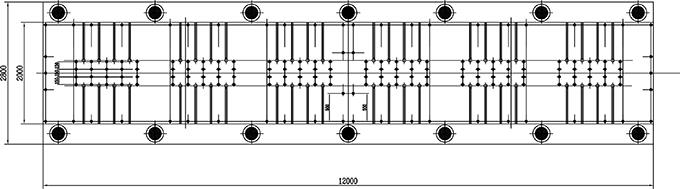

■ This press adopts three-beam and multi-column structure. The beam adopts integral beam with good strength and rigidity. There are 6 pieces of 500ton main cylinders for simultaneous pressing. Meanwhile equipped with upper cylinders for knock out of the workpieces adhere to the upper molds .

■ Hydraulic cushion adopts multi-cylinder structure, and the positions of ejection cylinders are arranged reasonably. Hydraulic cushion adopts separated multi-group structure, and with reliable guidance to prevent bias load. Above the cushion is installed with hardened cushion plate, ejection carried out by several ejector rods, and the holes of the ejection are made according to customization.

■ The press machine has independent power mechanism and electrical system, adopt PLC control technology, touch screen display, button centralized control, and equipped with two mobile button stations, can be realizing inching , manual, semi-automatic three operating modes.

■ The working pressure and travel length can be adjusted according to the process requirements. The slide stroke is controlled by the displacement sensor.

| No | Item | Unit | Parameters | Notes | |

| 1 | Nominal pressure | kN | 30000 | ||

| 2 | Maximum pressure of slider | kN | 30000 | ||

| 3 | Return force of slider | kN | ≥2000 | ||

| 4 | Ejection Force | kN | 6000 | ||

| 5 | Maximum working pressure of liquid | MPa | 25 | ||

| 6 | Maximum distance between slider and bolster | mm | 1600 | ||

| 7 | Maximum stroke of the slider | mm | 900 | ||

| 8 | Maximum stroke of ejection cylinders | mm | 300 | ||

| 9 | Maximum Die Height | mm | 700 | ||

| 10 | Slide Speed | Fast down | mm/s | 180 | |

| Pressing | mm/s | 5-12 | |||

| Return | mm/s | 100 | |||

| 11 | Effective Bolster Area | L-R | mm | 12000 | Inside of columns |

| F-B | mm | 2000 | |||

| 12 | Effective Pad Area | L-R | mm | 850 | Total six groups |

| F-B | mm | 550 | |||

| 13 | Upper knock out Force | kN | 1200 | 200×6 | |

| 14 | knock out stroke | mm | 150 | ||

| 15 | Total Power | kW | Around 160 | servo motor pump | |