Video Link:

https://www.youtube.com/watch?v=7Ge_KjNJSiQ

https://www.youtube.com/watch?v=eyUkl64HZQY

https://www.youtube.com/watch?v=QhCqfjqooxI

https://www.youtube.com/watch?v=13QB7mDu2KE

https://www.youtube.com/watch?v=6KQZFgEN0nA

https://www.youtube.com/watch?v=Q2Ru3osLiuY

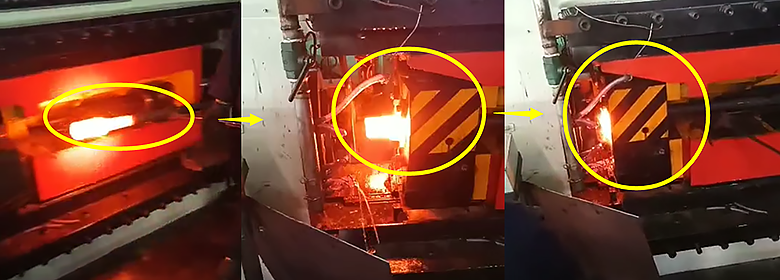

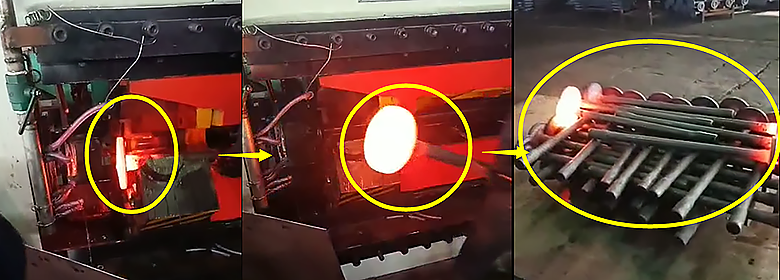

Application: Orbital forging press is the most advanced energy saving, material saving, less cutting , mechanical and electrical integration of high-tech pressure forming machinery and equipment, especially suitable for automotive half shaft flange, gear, CAM plate, rack, high strength bolt cap , and etc.

Features:

■ The machine have the advantages of low investment, low energy consumption, easy maintenance and easy operation.

■ Rotary forging pressure as conventional forging force of 1/15~1/10, the high efficiency more than 3 times of regular forging hammer, save raw materials, low noise, little vibration, and etc.

■ With the population of rolling forging production and promotion, which has become preferred and necessary equipment for automobile axle shaft forging processing, and made a great contribution for automobile axle shaft forging.

* Provide Customized Personalized Service

| No | Item | Unit | Parameters | Notes | |

| 1 | Maximum force of master cylinder | KN | 3150 | Adjustable | |

| 2 | Maximum force of mold closing cylinder | KN | 250 | Adjustable with pressure of master cylinder | |

| 3 | The maximum force of locking cylinder | KN | 250 | adjustable | |

| 4 | Maximum force of ejector cylinder | KN | 200 | ||

| 5 | Rotaty head tilt angle | º | 2 º | ||

| 6 | Track motion of rotary head | Circular | |||

| 7 | Maximum diameter of forming disk | mm | 300 | Final forging temperature ≥900℃ | |

| 8 | Maximum diameter of holding billet rod | mm | 100 | The thinnest part of billet rod | |

| 9 | Maximum length of holding billet rod | mm | 1500 | ||

| 10 | Maximum stroke of master cylinder | mm | 500 | ||

| 11 |

Speed of master cylinder |

Maximum Forward | mm/s | 70 | |

| Working | mm/s | 30~50 | |||

| Maximum return | mm/s | 100 | |||

| 12 | Total motor power : | KW | about 130 | ||